John@Outfront

Forum Moderator

- Apr 30, 2021

- 1,656

- 2,421

A friend of mine has a wicked sandcar and he needs a stronger tranny. he currently has an S4 and looking at doing an S4D

questions:

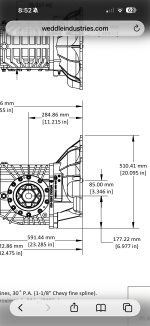

i assume it has the same mounting for the nose cone area. i Know the bellhousing has a different mounting pattern but is the length from nosecone to the bellhousing mounting the same as the S4?

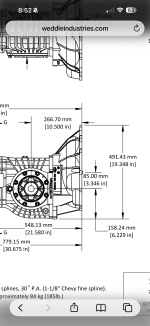

i also assume the shaft spacing is the same too so the motor in relation to the drive flanges--is it the same or would the motor be higher? i ask because the room is really tight where the motor resides. is the measurement of drive flange to drive flange the same so axle length doesn't change?

his current setup uses the old adapter plate set up, does the chevy bellhousing push the motor further back

asking for a friend

questions:

i assume it has the same mounting for the nose cone area. i Know the bellhousing has a different mounting pattern but is the length from nosecone to the bellhousing mounting the same as the S4?

i also assume the shaft spacing is the same too so the motor in relation to the drive flanges--is it the same or would the motor be higher? i ask because the room is really tight where the motor resides. is the measurement of drive flange to drive flange the same so axle length doesn't change?

his current setup uses the old adapter plate set up, does the chevy bellhousing push the motor further back

asking for a friend